About Polund

History

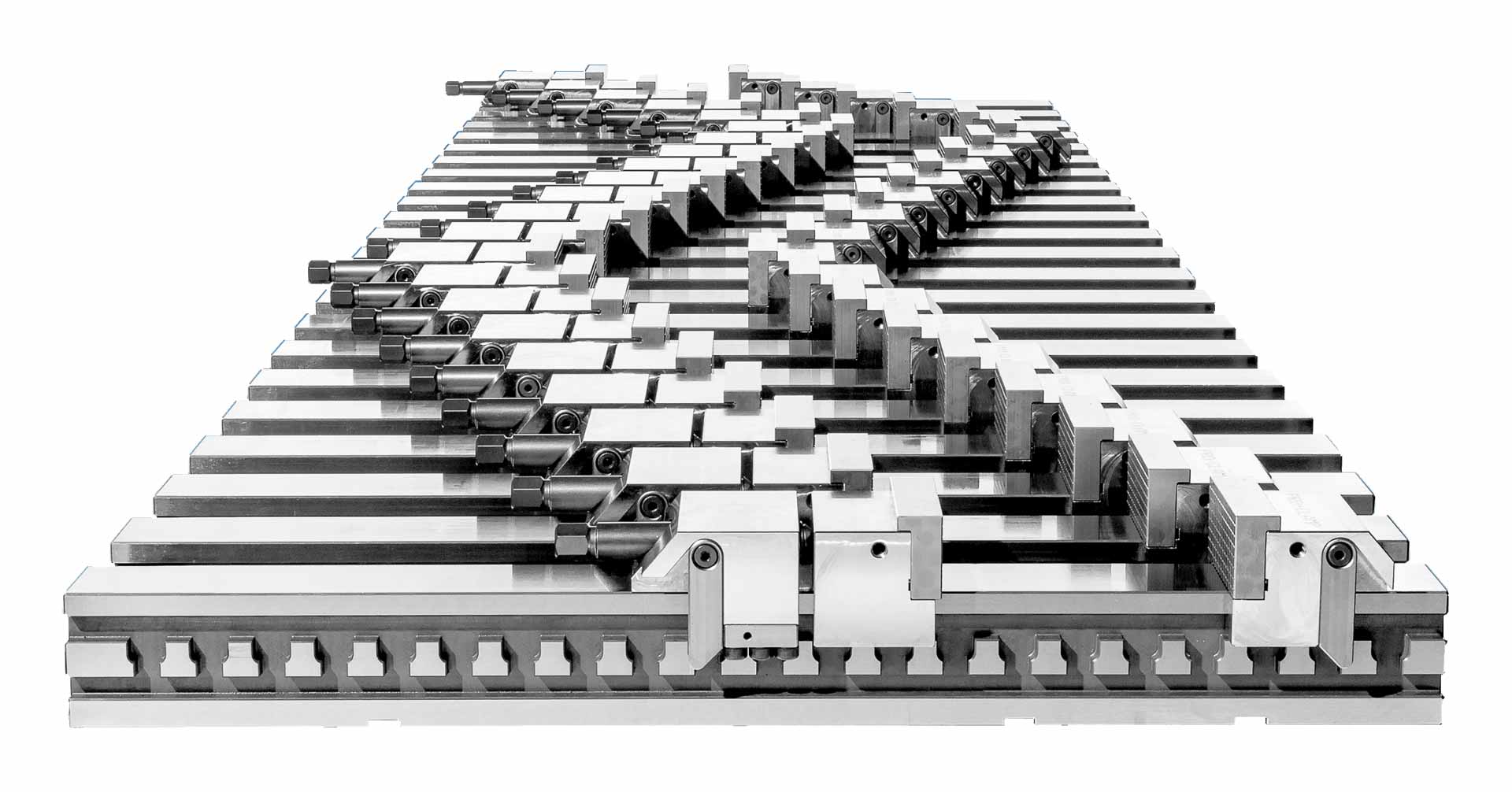

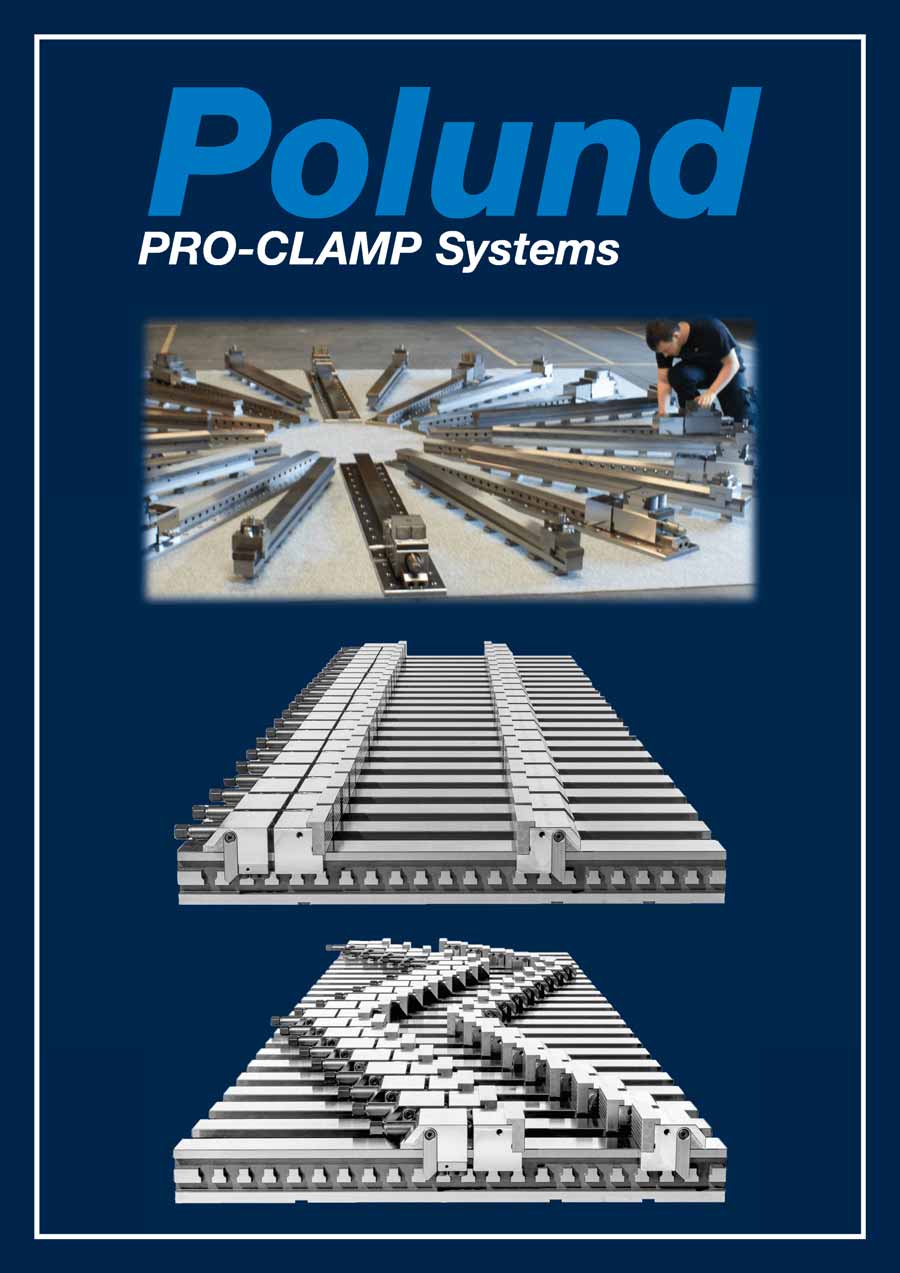

Polund A/S was founded in 1998 by Lars Pors and Ole Tolderlund. Both have a solid background in metalworking, and initially Polund A/S was primarily involved with subcontractor work. Polund A/S provides subcontracting work especially for milling and surface grinding, but today the most important part of the turnover comes from Polund’s own brand - PRO-CLAMP Systems.

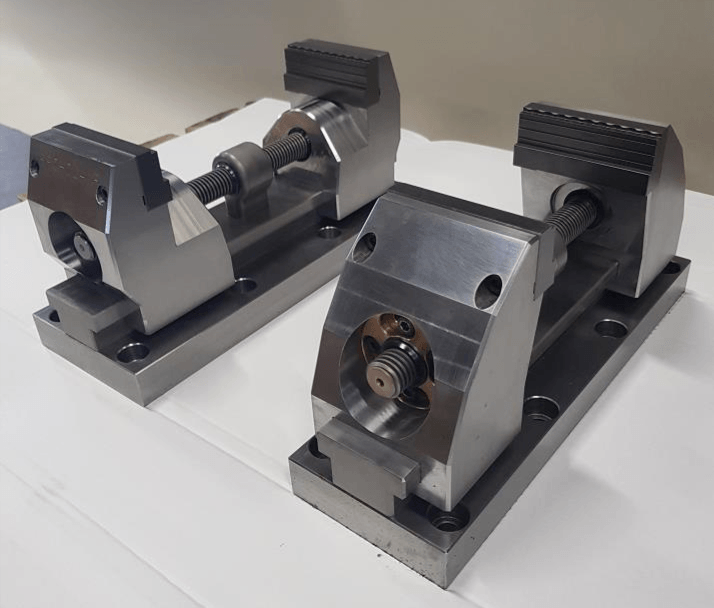

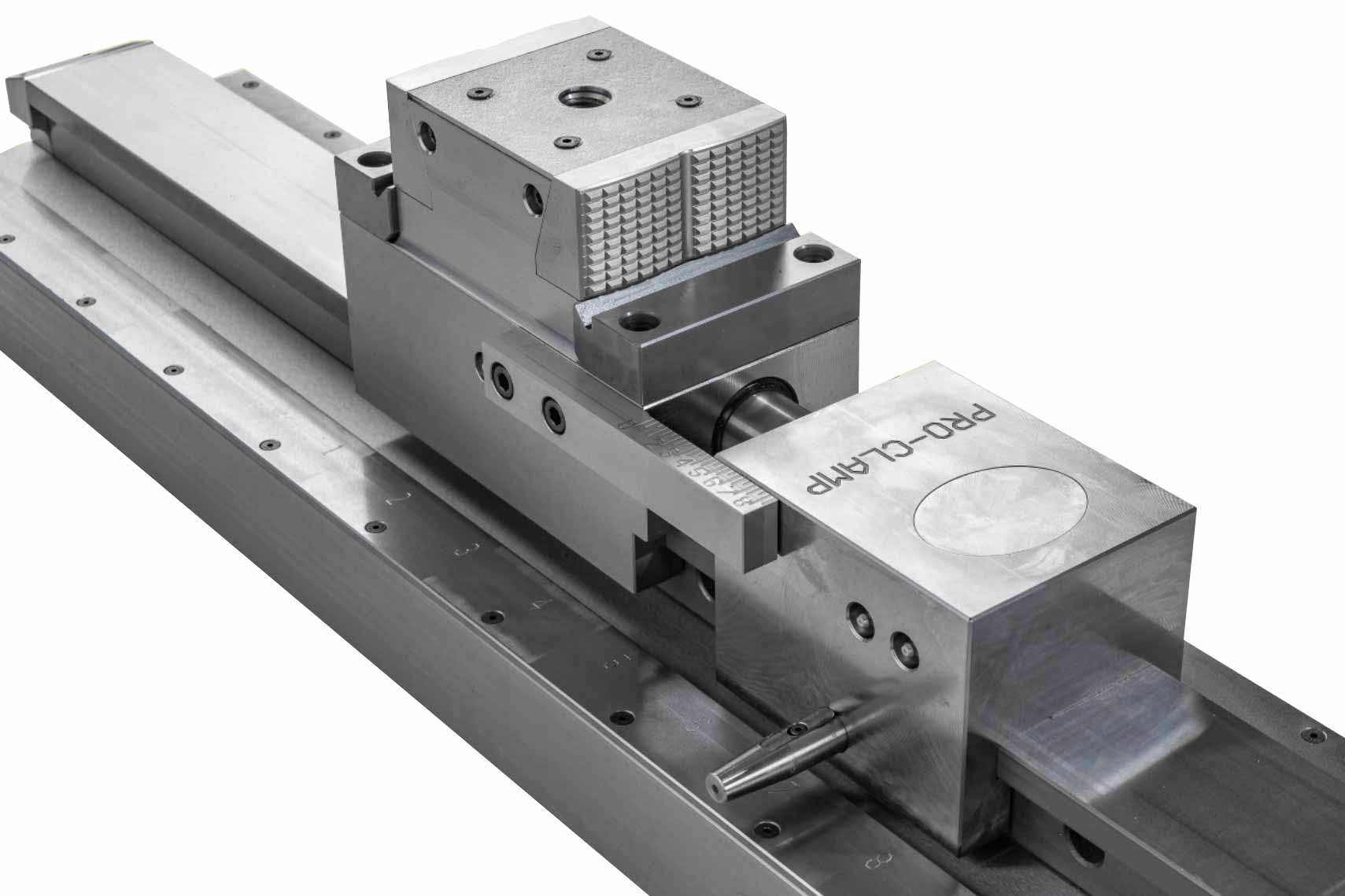

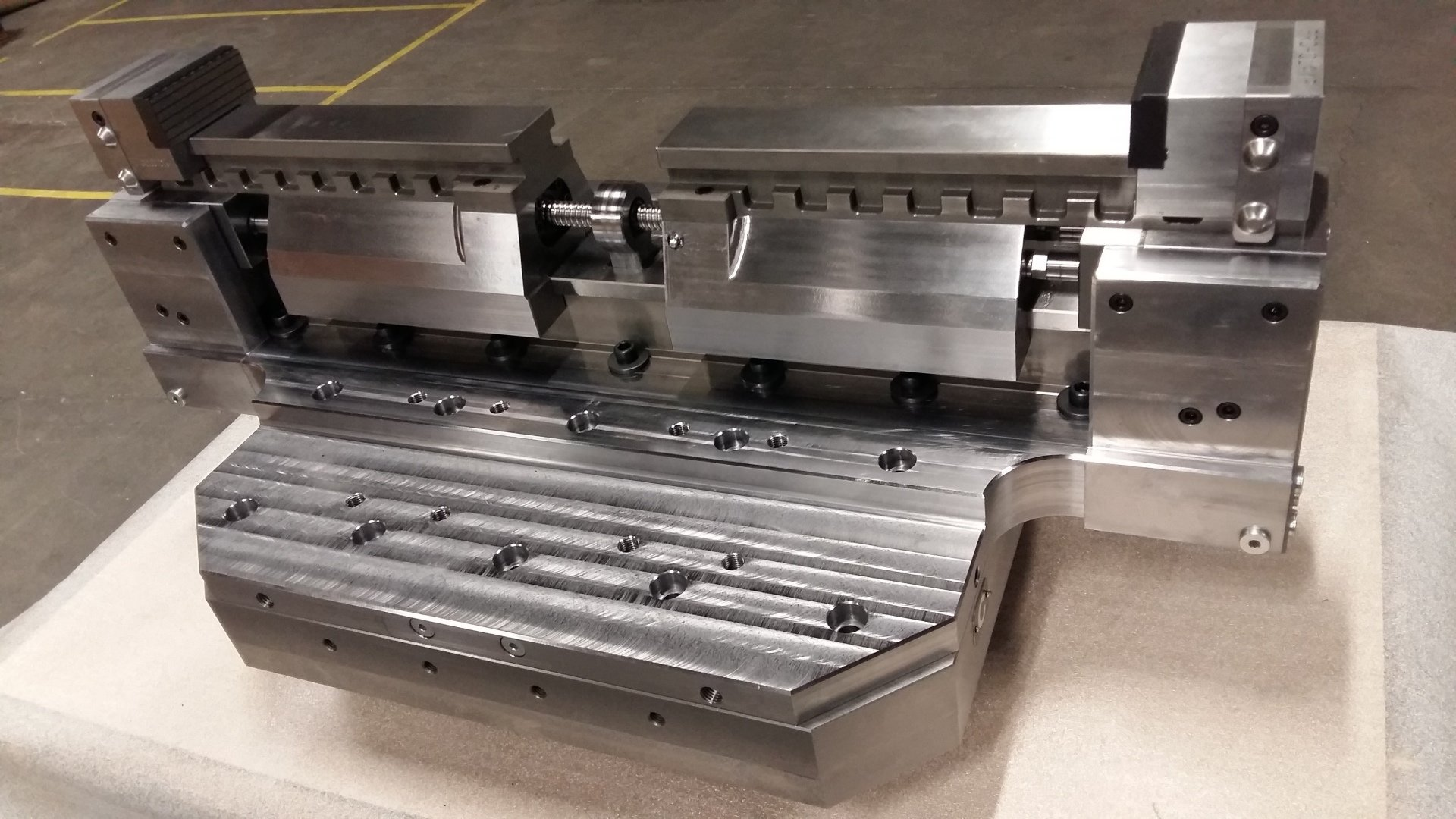

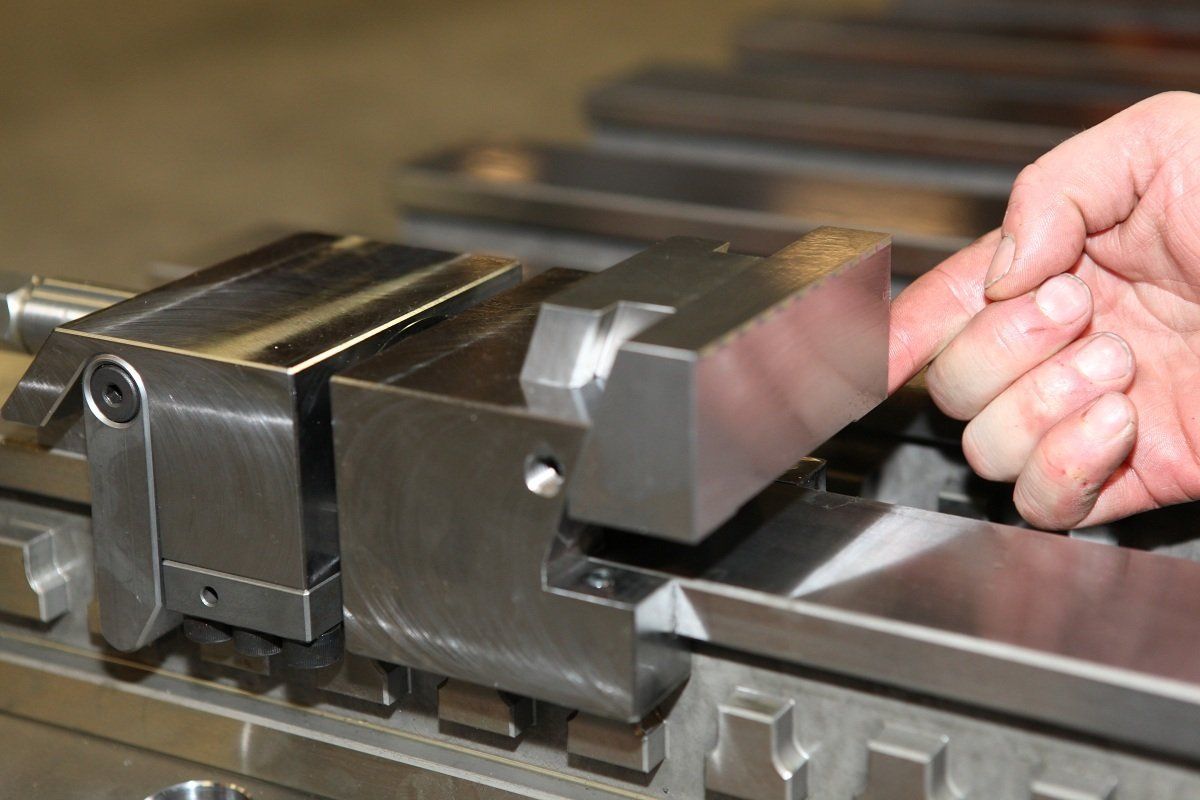

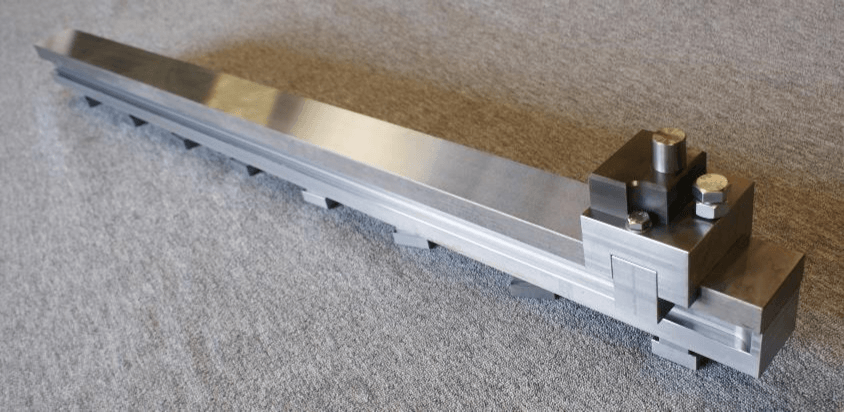

PRO-CLAMP Systems is a unique program in clamping that makes the adjustments and cleaning much faster, and thus frees up a lot of extra production time on the customer's existing machine park. The invention of the PRO-CLAMP System was 14 years ago, and the reason was that Polund A/S wanted to optimize its own production. "We thought we could use our advanced machinery better if we did not have to spend so much time on adjustments and to removing chips," says Lars Pors. Today PRO-CLAMP Systems has advanced considerably, so Polund A/S offers dedicated customised solutions and designs individual clamping tools, so the customer can reuse all their previously purchased jaws.

Vision

It is our vision to constantly be one step ahead with strong clamping solutions, which save time and thereby increase the production capacity of our customers. We want to be the most flexible and dynamic partner in the development of new and better production methods, where our products are used.

Mission

It is our mission to help our customers to leverage their production capacity optimally. Therefore, we offer fast and flexible clamping solutions to each individual metalworking machine where cleaning, adjusting and clamping of many items can be done in minimal time.

Values

At Polund A/S, the customer is in the center. We face our customer's challenges and solve in close cooperation all customer’s clamping needs. We challenge any customer with our special knowledge, so that we ensure we deliver an optimal solution, and not just what the customer thinks they can get. We respond quickly to any request, and ensure that every query is answered, before we return quickly with a proposal for a solution. Our employees are kept updated with the latest knowledge, and our entire production and management apparatus is kept in top condition, so that we ensure that we always deliver the best quality.